The hits keep on coming with this pandemic. In the last week there has been a consolidation of efforts to lock down Colorado and most of the country. As cases of COVID exponentially go up in the country, PPE gear is lacking in almost every community and hospital in the country.

With the lack of PPE a new focus has been health organizations and governments looking for support from the maker communities to 3D print components for PPE gear for first responders, and medical professionals.

Maker community activated

It has been a bit confusing to figure out how a 3D printer owner can get engaged to help. There was calls to action from various members of local and state government but the actual ways to get engaged was confusing. There has been a number of organizations that have come online to help. Whether it is private companies directly helping, or non profit orgs sprouting up to organize the efforts there are may ways to help.

Below is a list of Colorado and National coordination and networking resources:

- State of CO Volunteer website: https://covrn.com/ – This is the CO Gov website for volunteering info and registration –

- Make for COVID Colorado: https://www.make4covid.co/ – A group to coordinate 3D printing capacity and volunteers for specific asks in Colorado –

- Genesis Plastics – https://www.genesisplastech.com/ – is laser cutting face shields and needs the 3D community printing the head halo to hold them. Their design is simple and fast to print. To get involved please email : sjenson@genesisplastech.com (as of 3/27)

- Make The Masks: https://www.makethemasks.com/ – A national coordination effort to print PPE for medical professionals.

- Billings Clinic: https://www.billingsclinic.com/foundation – A Montana medical clinic/system rallying printing support to make PPE Masks for their clinics –

- Matterhackers COVID: https://www.matterhackers.com/covid-19 – Printing support and info – you can register to suppoCCrt the effort and be engaged by them and other organizations to print needed gear:

- 3D Printing Colorado @Facebook : https://www.facebook.com/groups/1891346274423444/ – a Facebook Group for CO printing that is also acting as a bit of a rally point/coordination hub for a lot of the COVID PPE printing discussions.

- North Colorado Face Shield Project: https://www.nocofaceshieldproject.org/ – A Fort Collins based shield project, using the Prusa designed shield.

Masks vs Shields, and getting to work

Face masks are 3D printed filter masks that use n95 filter material but the mask itself is printed with firm plastic. These are needed in many places right now as you can see from the asks above.

Face Shields are plastic guards to protect the medical professionals face and mask, this can result in the face mask lasting longer and protect the pros eyes. Both are critically important.

I started printing face masks but after some discussions about urgent needs, and looking at some of the delays I saw in getting the go-ahead on the masks I contacted Genesis plastics. Genesis responded and they immediately asked for assistance printing the head bands/halos for face shields. They are cutting the face shield material but needed the head bands. With the confirmation that they needed assistance I fired up my printer to go to work for them.

The Genesis ask was clear:

Thank you all for contacting us and offering your 3D printing services . As you know we’re working with the Colorado COVID-19 Task Force to supply face shields to the medical community. We’ve made it through the initial test phase and have been asked to supply 500 of these immediately and 6000 in the next 7-14 days.

We will need at least 500 parts at our building ASAP and believe this will require a 3-D printer community effort. What part of this effort would you feel comfortable supporting, and please provide feedback on fair pricing for your efforts?

Those of you that have already been helping us, we say thank you and this is a call for even more halos and your continued input as well.

Genesis has detailed directions a asks for these halos in terms of print settings, plastic type to use, etc… They supplied STL file with the design.

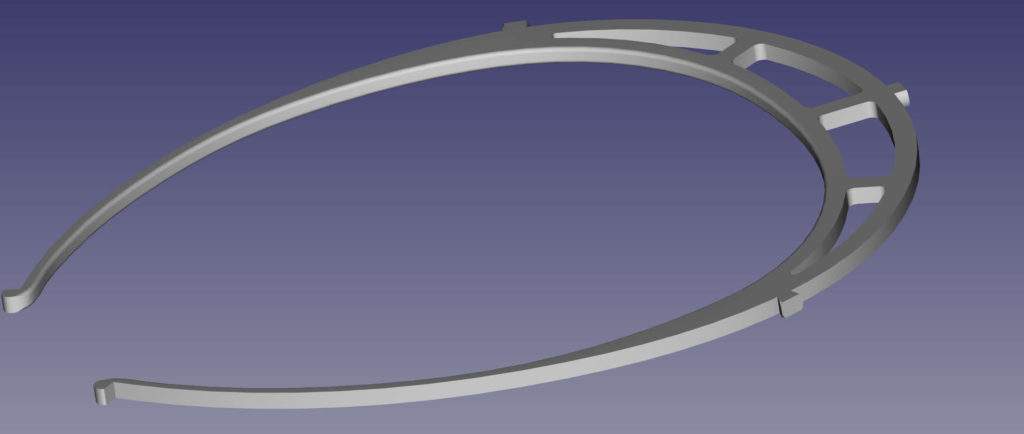

After printing a test file, I noticed the edges of the halo that goes to the head were sharp edges. So took the file, and put it into FreeCAD, and modified it to clean up the edges, and put nicely radiused edges around the head side. I sent the file back to Genesis and they approved it and I believe are now using that design for others. I also have posted it and am trying to coordinate this with a few different 3D printing communities.

A link to the STL for this updated file is here: (Contact Genesis above if you are going to start printing these to verify they still need them.) https://1drv.ms/u/s!AtuhT174YsbYldUJ_vZOJApU6nqHqw?e=q6eWw8

Mass production

Once I had the print settings sorted I have been printing every hour I have been awake for ~2 days so far and am at close to 60 halos printed. By Monday morning I hope to be done with 70 – 100 and get them delivered to Genesis in Greeley, CO.

My printer has been setup now for fast production, where it wont power down between prints, I get a text message when a print is done so I can go swap the job. Being in “Stay at Home” lock down in CO this makes it pretty easy to be attentive to this.

With small tweaks to the print settings and working on pushing the print hard and faster than I normally would, I am getting 2x halos done in under 55 minutes now. PETG is a finicky filament so I cant push it much faster even though the printer could.

Once I exhaust the filament I have for this ask, I may switch over to face masks or any other critical PPE that is requested.

Wear and Tear and Maintenance

Running a printer essentially 18 hours a day printing non stop has a good amount of wear and tear… at some point coming up I will need to take the printer down to check the linear rails, belts, etc… This printer has been running for almost exactly a year now since I designed and built it last year, and besides for minor tweaks hasn’t needed any major maintenance. But I am coming up on needing to lubricate the Genuine HiWin linear rail components based on the MFG maintenance schedule. The belts being all very high end Gates belts seem to be holding up just fine.

So far the rails look clean and well lubricated, but I need to be careful to not have the rails start wearing as that could be expensive to fix. I am watching the printer closely and listening to the weird ass noises it is making to ensure I dont cause damage. At this point the nozzle stays at 250C temps all day long and the heated bed sits at 75C all day. So far its holding strong, and even if one hot end does have some kind of failure I have the second one I can use.

Leave a Reply