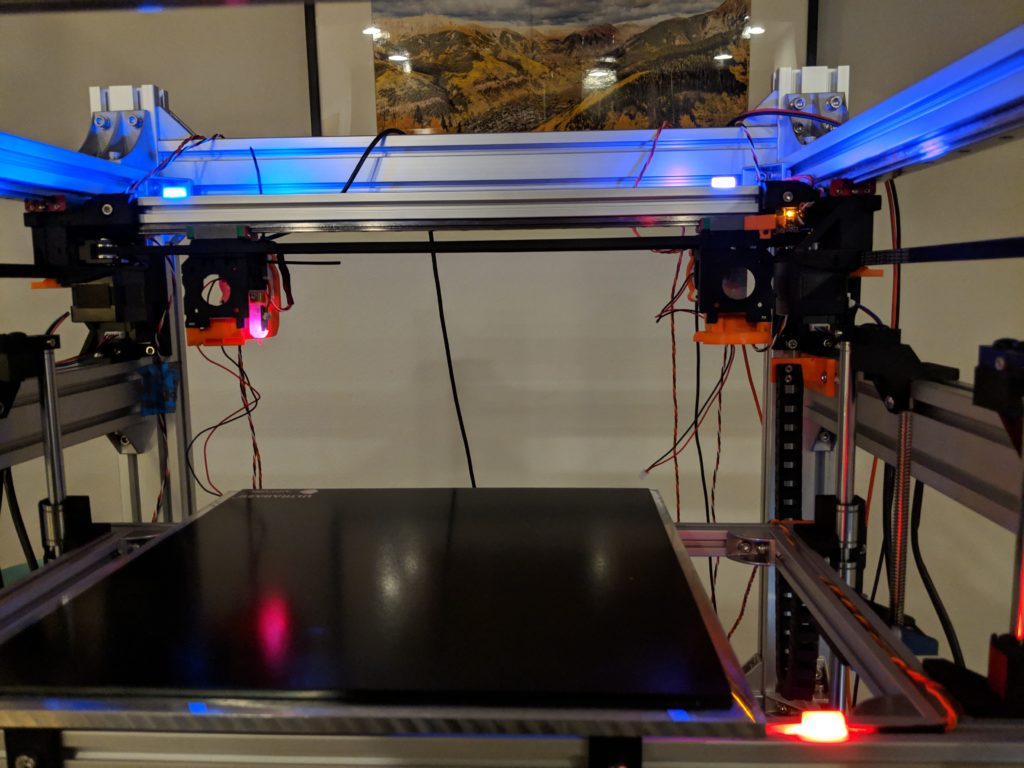

LED madness!

Tonight was some code work and LED wiring. After ordering the wrong polarity of RGB LEDs last time I got the proper ones in for this main board (Common Anode). They are setup and coded to have different colors for various actions. During printing they will show which hot end is hot and active or heating, which is stand by (for dual extruder prints), or which is idle and not used in this print job. The bed will also slow when it is cool, or heating up, or at temp.

This takes up 6 fan headers on the Duet3d Duex5 board. Leaving me with possible too few fans for the printer… so I gotta work that out. Researching if I can use the extra heater headers for some fans… I think I may be up against a hard limit on the board though for addressable fan outputs.

These are all novelties, but … I dig it 🙂

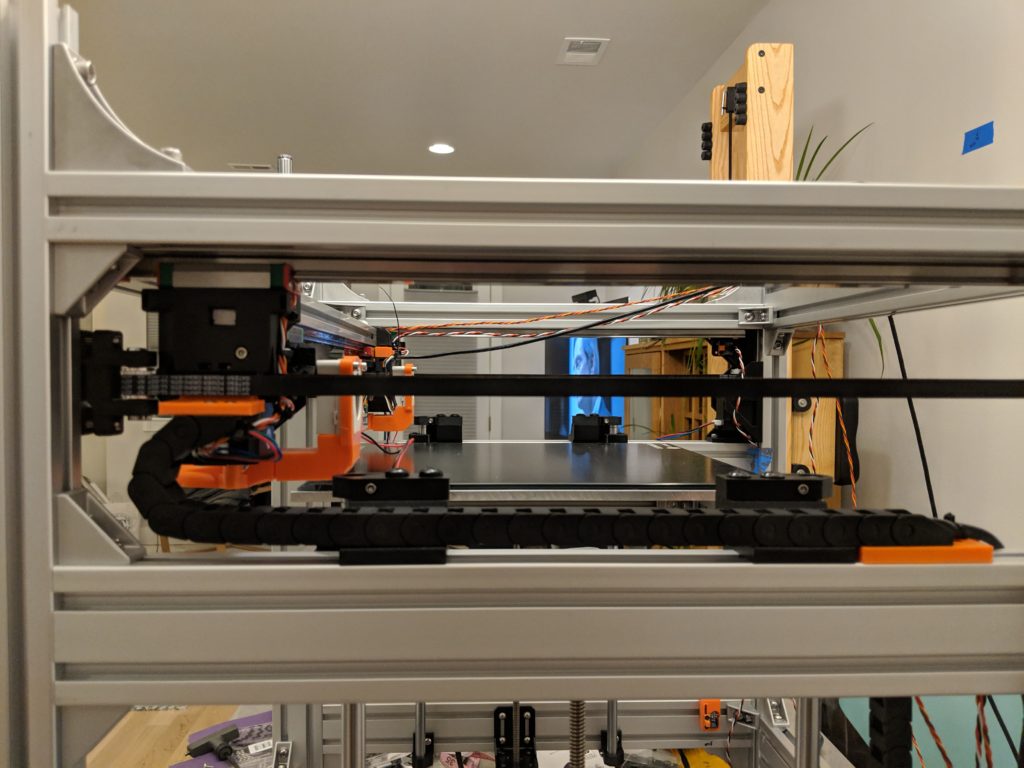

Wiring:

Besides that I did a bit of playing tonight with drag chains for handling the wire routing.

After doing some testing I found that the cable chain cogging I can feel in my hand when I use it will have virtually no effect on the printer given the masses at play. I had to print an extended cable holder for the back of the Y Gantry and some wire management bits down on the frame, and it seems to work.

The Cable chains have a bow to them and don’t lie dead flat… I am unsure what effect this is going to have, or what to do to remedy it… It may not be an actual issue. So we’ll see.

I did design the upper Z-Axis hangers specifically to give clearance for a cable chain to be used on both sides. So that worked out well.

I’ve setup the Table and the Y gantry with this. So far it seems to work very well and took a total of an hour to design the 3D printed parts to enable using this. This will leave both the print head axis (X and U) with overhead cables and that is it for “loose” wires.

Exhausted:

I am legitimately becoming exhausted on this project… besides for sleeping, work, and the occasional meal… this thing has consumed my life. Going to put the project away later this week for family coming to town. This project has literally consumed 2 months of time so far from designing, testing, printing, ordering, and doing all that over and over again. It’s very rewarding, but damn it’s taxing! The reason I have the time for this right now, is I’ve started a diet in early Feb that really has me laying low for a couple months as I shed weight before I start working out again… So lots of free time for this.

I am aiming to have at least one extruder mounted, and the heated bed figured out by the time the project gets put away for few days.

I still need to get the heated bed into a shop to drill the mounting holes for the silicone heater, and corner mounts.

Leave a Reply