I’ve been fortunate over the years to NEVER have had a nozzle clog on me… until shortly after the picture from yesterday’s post about the Carbon X prints starting.

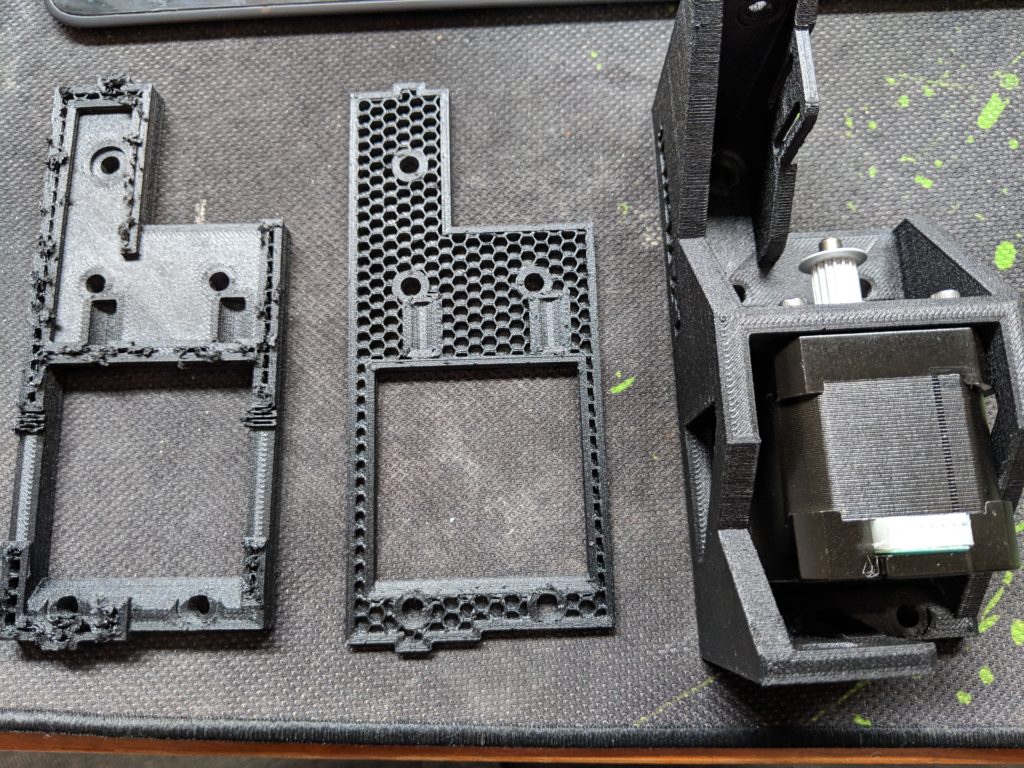

I looked over and saw the head moving mid air and nothing coming out, and the print looking mangled. Welcome my first nozzle clog, and it was a doozy! Not only did the print fail from a total clog twice, but the hob kept chewing on filament and put a ton of ground up filament in the extruder housing… so I had to clean all that out.

I ended up doing a few cold pulls with nylon to clear it up. Note I tried to do the cold pull with the CarbonX, but it just snaps. Regular Nylon works MUCH better.

Then I went back printing and had another nozzle clog even faster! … WTF is happening?

Retraction…. I think.

I had retraction set to 1.3mm on a e3d V6. That hasn’t been an issue with ooze prone filaments in the past (PETG primarily), and is under the 2mm max for the V6. The print height was also at .2 which is a little below the recommended .24 for a .4mm nozzle for this filament. People have reporting printing at .1 and .12 with this filament so I dont think layer height is a big issue, especially using a geared extruder like the titan.

So I knocked retraction down to .5, increased layer height to .24, increased speed a little (to keep things moving) and upped the extrusion my 1% to 100% ( I wanted to do that anyway). After that I ran a print of another Y Axis motor mount (largest printed part on the printer) and it was a success!

From looking at how the failures happened, and seeing on some of the cold pulls how far from the nozzle melted filament was… I think the retraction was pulling some of the molten plastic into the heartbreak and letting it cool there. So I am keeping the retraction good and low for now.

The nozzle I am using is specifically supposed to be better to avoid clogs than normal hardened nozzles. So that also leads me to believe it was the heartbreak side of things. This hot end has the upgraded titanium heartbreak which should cause a more defined “cool” zone to form in the heat break due to worse temperature conductivity to the heatsink. This could easily be why at 1.3mm retraction enough very tough and abrasive filament got melted up there to block the entire thing from working.

The 3rd attempt worked great! No clogs, and the print quality was pretty good. .24 is bigger than I wanted for layer height, but it looks fine on these big parts. Also generally thicker layer heights yield stronger parts.

So lesson be learned…. Don’t get to generous with retraction on high temp filaments like this on an V6 hot end.

A different kind of Jam – too much idler pressure in the extruder:

While on this topic, I ran into another failure the other day in a print… I thought it was a nozzle jam but it turned out not to be. I was printing PETG, and had cranked down the extruder idler spring too far. It was compressing the PETG into a pancake as it rolled though and that caused it to stop making it through the orifice into the hot end.

For CF Nylon you can crank that thing down as far as it will go given the brutal strength and hardness of this filament, (and PLA to some extent as well, but not as much). PETG is too soft for that and deformed easily. This was eye opening, and made me pay better attention to the spring tension I use in the future.

I only noticed when I heard the extruder motor skipping steps or the hob skipping on the chewed up PETG that built up.

Learning a lot these days!

Leave a Reply