JK3D.us was “started” last year sometime; I bought a domain, hosting, installed WordPress, and then did nothing about it for close to a year while I worked to figure out what it was going to be. Everything seems simple at fist to sell some widgets online… then when you think about the entire logistics and customer aspect… it gets a lot more interesting.

A year of prep, and anxiety

I’ve run multiple small ventures in the past, some successful, some failures, but all consumed me when I was working on them. I don’t know how to go half in on anything and that is a significant problem in this instance as to go “all-in” on engineering and 3D design work could require more capital, space, time, education and commitment than I have right now. That aspect scared me and gave me pause before “launching” JK3D.

I spent months passively and actively working on how I am going to handle this endeavor. I watched other sites, businesses, and hobbyists, and how they were succeeding and failing. I also had to look inside to see what I wanted to be. The anxiety of failure built up over the year about if I would not be good enough, not be able to make products or services people would want or need, and if I would just waste time and money… I feel like I am OK at what I do with 3D work… but Imposter Syndrome runs strong with me.

So I had to approach this in a way that I limit my liabilities, costs, and obligation to the business in order to keep the operational expenses from dragging me down during slow times, and enable me to pivot as needed. I built the store/site on inexpensive prepaid hosting, using WordPress, and using tools, plugins, and other parts that do not require subscriptions… so if the site is slow, I am out virtually nothing. (Shopify, Etsy, etc… all have monthly costs or significantly higher operational costs than I am comfortable with right now. Month to month my store can run for under 10% what the lowest Shopify monthly would be)

Making JK3D.us my thing, not following anyone’s rules

I spent a good bit of time watching other local and national 3D printing services companies and how they work. They range from legitimate large scale services, where there are millions of dollars in hardware, slick websites, and clearly massive companies. These offer incredible services, extreme variety, and high cost.

Then there is the other side, where a hobbyist, buys a dozen sub $300 printers and turns out widgets, fidget spinner kind of trinkets, and low end runs of items. These folks have everything from basic to very nice and slick websites, and most all of them make it seem like they are a power house of manufacturing and design. They will do and say what ever they need because many of these are people who (especially during the pandemic) are using this as their primary income now.

The price of services, prints, etc… vary wildly for the hobbyist turned business sites. Most play it close to the chest, but I did queries with a few to get some idea of rates and such. Some think they are offering services on par with mega printers like Shapeways, and others keep it dirt cheap and low end. Every single geek on various FB groups slinging 3D printed wares swears you need to work in volume.

So … what do I want to be? A hobbyist that makes it seem like I am a big high output factory? A hobbyist that doesn’t value his goods or services? I conferred with a number of close friends and came to a good balance and solution to this.

JK3D.us is me, and I am focused on the customer

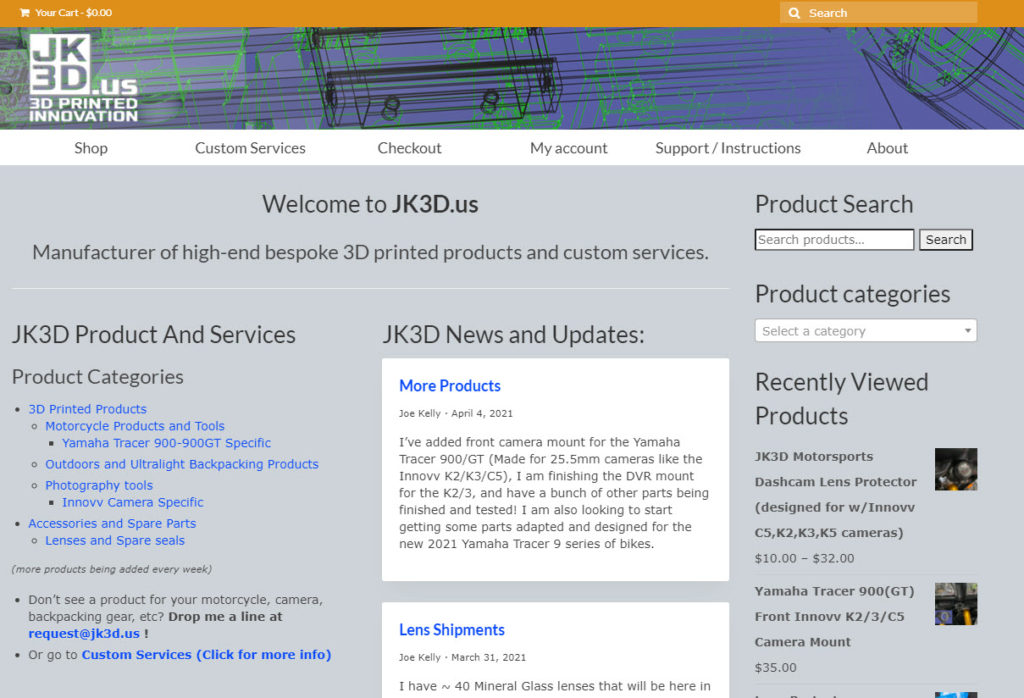

I changed the site around, and clearly explain on the site that I am the only person running JK3D and I have accountability for any failure and success. I added a clear history and mission statement to the site focusing on that. I am making it clear that if there is ever an issue there are a number of emails direct to me.

I do not want to be a guy in his basement with a bunch of shit printers that are constantly in a state of failure, but still over promising to customers. I want to be customer and product focused, and not focused on production runs, or pretending to be something I am not.

To do this I am leaning in on my own custom designs, and my strengths at this phase of the business. I can ramp the business up slow and controlled and learn from any mistakes or failures that happen along the way.

A failure happens along the way

With the launch of JK3D.us I was looking for markets and ways into a customer base with an existing product. It was timely that Innovv was launching new cameras, and I have products designed, tested, and refined for production for their new and old cameras already. One of the parts – a lens protector for a dash/action cam – is made in a way that would actually be difficult for most other 3D printers to make due to the high end multi material print that it requires. The body is printed with high end and highly abrasive CF-Nylon + soft TPU filament printing together.

Because I realized I have a unique product, people were asking for, I executed fast on making a solution available. So JK3D was really launched with a action cam lens protector 2 weeks ago. I offered a unique product no one else has, that is simple and fast to make, and offers a quality level no one else has anywhere in this industry. I sell a lens protector made of high end materials, with a Sapphire lens, that looks good and has a warranty. I listed the product and versions… and they sold.

Then, when the first lens protector was delivered, that customer emailed me saying it didn’t fit. “How could this be? I took engineering designs from the MFG of all the cameras to ensure I knew it would!” I thought.

I worked with the customer who was very helpful in taking some measurements of the Innovv K5 camera he has. After a few back and forth I realized, I verified the design off a bad engineering spec from Innovv. They had the camera sized as 25mm diameter (same as the other versions of the cameras) but the actual diameter is 22mm. By engineering standards that is a gigantic difference. I knew I had an issue… I sold 8 of these in the last couple days and potentially all were going to be used on these K5 cameras. (The product still works perfectly for the other 4 models of camera but I had to take a worst case scenario stance.)

The fix was simple and I had a rough draft ready before I even got the second confirmation from another customer of the size mismatch. A simple rubber/ TPU sleeve that is thicker would fix this problem.

Immediate responsibility and customer service

As soon as I verified that the size was different from my spec, and I knew I could fix it. I took a number of steps before even focused on the full repair.

- I updated the site to show no new shipments or sales of the lens protector would be available for a few days.

- Emailed all the customers, explaining the issue, and explaining they will all be receiving a replacement part to let the protector work with the different sized camera.

- I updated the site again to have a K5 specific fitment option for the lens protector.

- That same day I had the redesign fully done and tested, and ordered the black TPU I needed (due to its thickness, I didn’t want to use the clear TPU for how it would look.)

Two days later I had the entire replacement part run completed, and packed to ship to the customers (two days ahead of when I told them to expect the replacements to be shipped). The customers who helped me with measurements to validate the design I also sent some spare lens protector lenses to them as a thanks. Each envelope also included a small letter explaining the issue and the solution.

Exercise and repetition

Was all that needed for a small run of products that cost under $20 per customer? Possibly no? Every one was incredibly friendly and understanding, most customers even offered to pay for the fix! But as I said above, I am running this as customer focused and high quality as I am able to. Failing my customers is failing my concept and reason for doing this, so going all in on resolving this ASAP was and is incredibly important.

Mapping out and noting the entire execution of how to address, halt, and recover from an issue in the future makes me a better business owner.

This is why I wanted to start small, controlled, and in my strength so when something does go wrong I can limit the issues rapidly. As the store grows (hopefully), and as I look toward larger, and potentially riskier opportunities, this experience will give me confidence.

Next Steps

With the first iterations of the business already under way I am taking a bit of a planned pause in terms of advertising and finding more customers. I am now loading up the site with more products. I’ve learned that one-off products I designed for myself are not always great for “mass production”. So I am taking every design and focusing on tweaks or redesigns to make them sturdier, faster to print, and have some more refined style/look.

I am in the middle of that process, and once that is done I am going to look at the next parts of being a small internet business… SEO, advertising, and finding markets I can grow in. I have specific markets I want to focus on coming up and I will need to leverage my way into them. Whole new step coming up!

Now… I am also working on some of my other motorcycle stuff… but thats another post!

Anton Claessens

Hello

I have heard that you can make an adjustment for the saddle for a Yamaha mt09 tracer year 2018 so that the sitting position improves?

If this is the case, what are the costs for making and sending it to Belgium

regards Anton