After the drama of having the nozzle clog on the printer a few days ago, and making a number of changes to address that… I found many of the changes had a direct and negative effect on the tolerances and accuracy of the prints! I printed one of the Y Carriage blocks and went to fit the assembled MGN12 rail and 2020 extrusion into it… and it didn’t even kind of fit. The measurements were off in every single dimension between .5 and 1mm (which is football field for what I am aiming for).

Using the PLA test part that I did proof of concept testing with, I was floored at how dimensionally, the carbon print was all over the place. Not a specific X/Y/Z offset, but random based on the complexities of various parts of the print.

Temp, Extrusion %, Print order

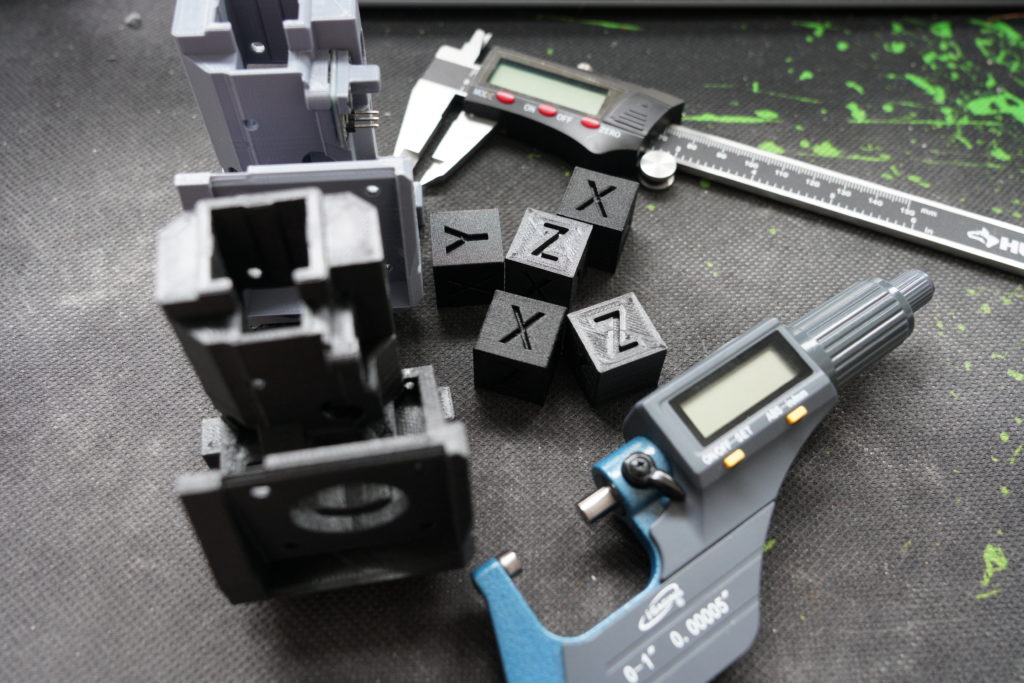

As you can see from the first pic, I went through a number of calibration cubes again to see WTF was going on here. They echoed the same results. I looked at the changes I made to the printer to fix the clogging and I think I found the problems.

Extrusion % – I had it back to 100%, in some earlier testing no issues seemed to be evident at that, the parts were strong and no visible over extrusion. But I think some of the test prints masked the real issue. Since I was printing inside-out, the excess material just made the prints bigger than they should be as it squeezed out to wide extrusion width. I tested backing it down all the way to 95% and it prints cleaner, still strong, and tolerances came into where I wanted them (under .002mm off from the perfect)

This is compounded by the narrow extrusion width I am using .42mm for a .4 nozzle. That is a tight extrusion but needed to ensure the nylon has good adhesion with the surrounding layers. The normal recommendation would be .48 for this nozzle but I saw extrusion separation doing that. So it makes sense the extrusion% would need to be cut back as well.

Temperature – I also was looking closely at the Y Carrier hub and found evidence of the filament being too hot. So I knocked the temp down 10C and that also helped make the print a bit more clean. I moved it up 5C from the first prints when the clogging happened. Still no strength issues in testing at that temp, it also helped some bridging. I was at 270, now down to 260C.

Print Order – I did all my calibration prints outside-in. This should in theory push any difference in extrusion material and width inside the print vs bulging the outer profile. This causes some additional issues with bridging and angled surfaces, but 45% surfaces seem to handle this OK. I am testing now to see if that works on complex prints. I calibrated both inside-out and outside-in prints with cubes so I should be able to go back the other way if needed.

The costs of these mistakes?

So these mistakes have cost me probably 1/4 of the roll of CarbonX from messed up prints, clogs, etc… So I’ve ordered a second $70 roll of CarbonX since I’ll need more it seems. (and it will be a good filament to have around for other projects)

Time as well, I’ve burned most of this week printing stuff that wasn’t in tolerance. (Before the cloggs, the parts were on point in checks, its all after I fixed the clogging problems shit went sideways).

Make that Break three others… When taking pics for this post I dropped my phone on my desk accidentally… and it landed with the corner of one of the cubes pictured hitting the camera on my Pixel 2XL perfectly and shattered the camera lens on it.

So add another $100 warranty claim to the list of indirect costs 🙂 Thankfully I am well stocked on good photography gear, it’s just more of a pain to take pics of this project with that.

Lessons learned:

1. Don’t drop your damn phone on shit.

2. Phone protection plans pay off!

3. Pay close attention to the details in 3D printing, any small change to fix one thing could have a negative impact on other aspects. Especially when you are building things with tight tolerances!

4. Always order more filament up front, even when you are sure you wont need it.

Leave a Reply