Squaring up the Z Axis

The Z Axis mounted. Took a lot to get the LMU bearings aligned

The X/Y Gantry

Belt setup and the U Axis extruder

Belt setup for the X and U Axis

Testing Duet2Eternet out

Perfect clearance for the part coolers

Hall end stops working great

This weekend, a ton of progress was made. All 3 of the Axis were mounted and tested. Some wiring was done(or tested at least), and test movements have happened for all the major components.

Issues during the build out:

LEDs… I made a mistake by buying common cathode RGBW LEDs and found the Duet2 is a ground switching PWM controller for the FAN/LED headers. So I had to order new LEDs…

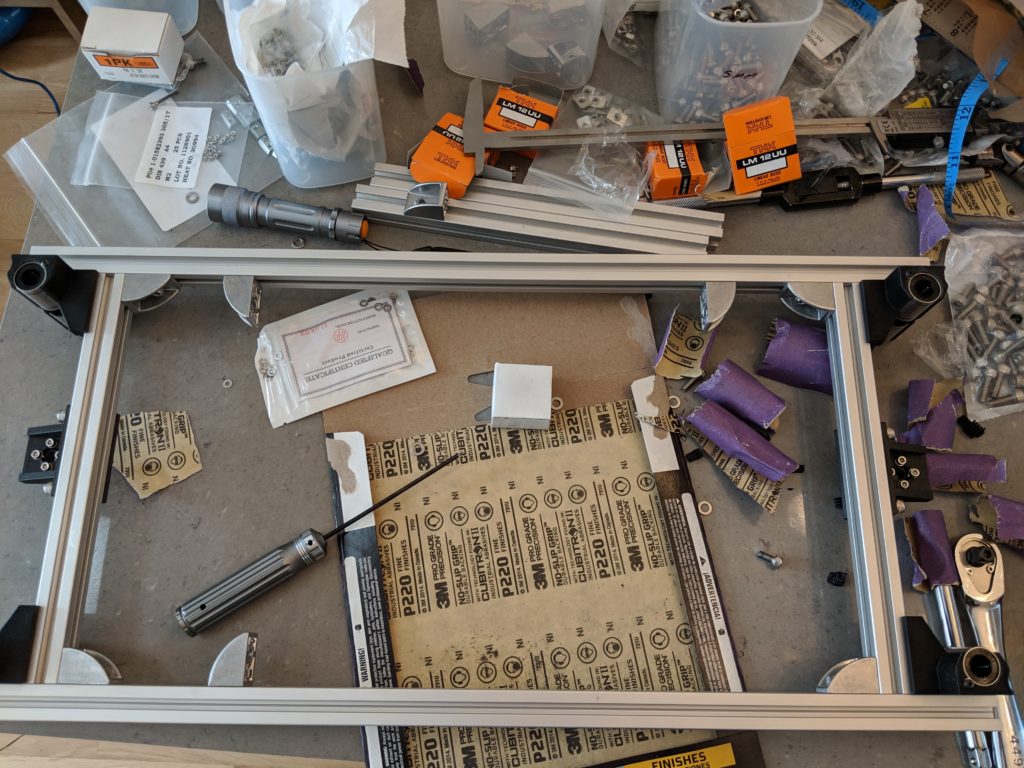

LM12UU bearing alignment. In building the Z table, the bearing holders seemed true, but the LM12UU bearings (8 of em) need to align perfectly in pairs, so that required extended sanding and truing of the bearing holder slots. A look at the sandpaper rings from all the sanding that was done.

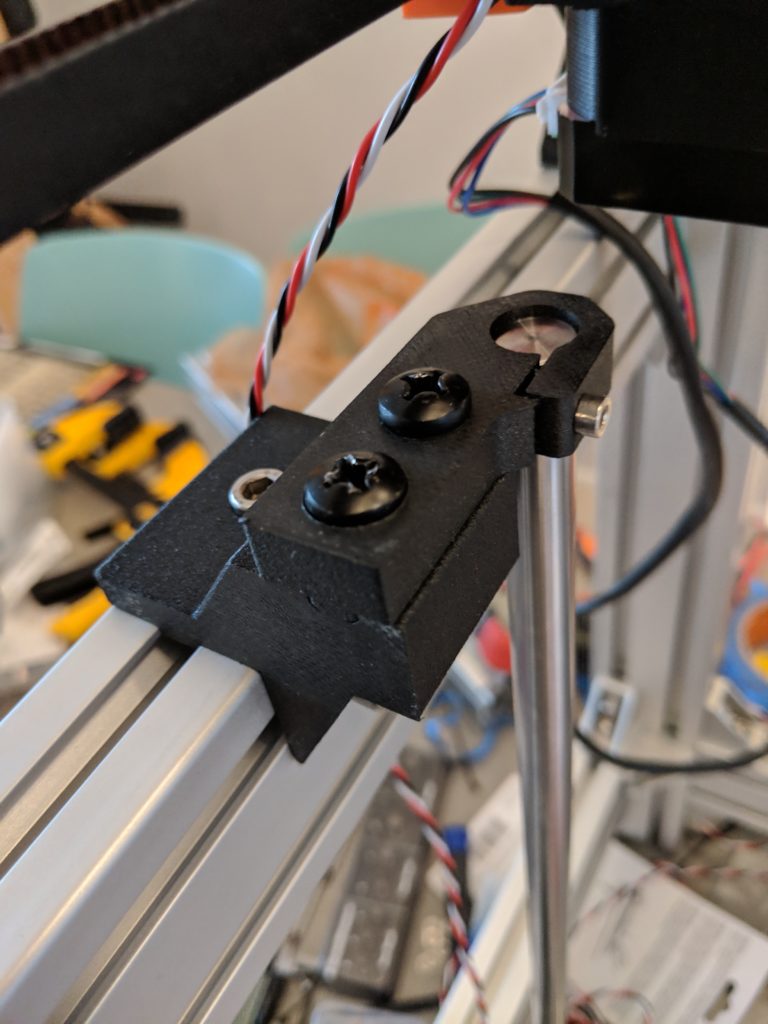

Bad filament = fragile Z axis linear rod hangers.

So While I am getting the printer working, I am unimpressed with the quality of filament I received from 3dXtech, this second spool has yielded some more fragile parts (strong but a bit more brittle). The upper Z Hangers are pretty complex in their design so it makes printing more complex. The angle they had to be printed at made the clamp area exceptionally brittle.

So I sat down and redesigned the mount to make it modular. This lets me print the upper hanger main body one way and the hanger clamp another.

This redesign has a multitude of advantages. I can tweak the hanger for alignment if needed, if I want to remove the Z table entirely I can just unbolt the top and not worry about messing up the bar alignment. Even with the brittle filament it works well.

Bad filament explained further –

2nd spool on left, 1st spool on right

2nd spool on left, 1st spool on right

2nd spool on left, 1st spool on right

So the drama around filament sort of crested this week with 3DXtech ghosting me when trying to get support for their inconsistent filament. As you can see above (the printer settings were exactly the same between the two), the quality difference between them was noticeable. Besides the fact that the filament wont print on Anycubic Ultrabase without PVA glue on it (the first roll printed fine).

It sounds like others are seeing the same inconsistencies from 3DXtech lately… so buyer beware.

Because of all this, I just ordered spools from Matterhackers (NylonX) and I will probably reprint a few of the parts on the printer I’ve done if the new Matterhackers filament lives up to the hype.

Beyond all that – the build went well. the X, Y, and U (second Extruder) home and move perfectly. I need to finish wiring up the BLTouch to get the Z table calibrated. There is a lot of coding to do on the Duet2Ethernet still but I am getting to the point that the printer can start to be tuned and refined.

Much more to do, now time to start packing away a lot of the construction gear for the printer.

Leave a Reply